SHINKAWA

SHINKAWA WIRE BONDER (MODIFICATION)

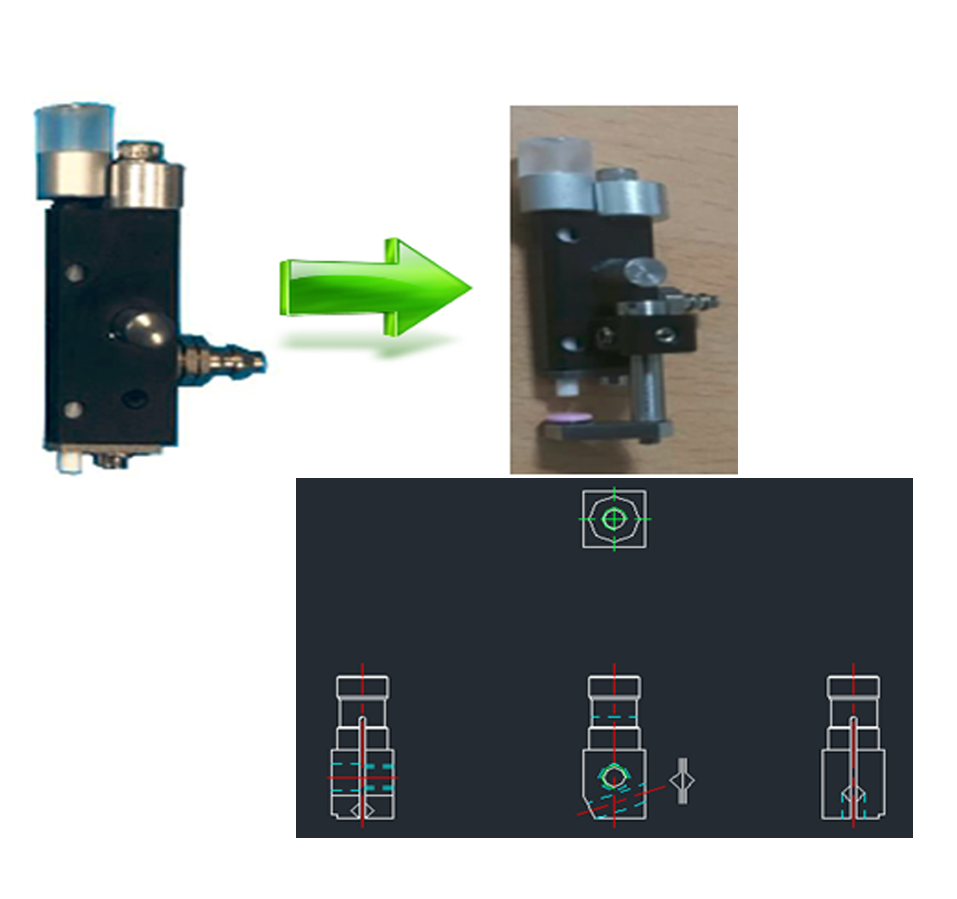

- Improve the Bonding quality by taking the modified Air tensioner where the problem was maintained in the original part. The modified parts reduces the wire vibration due to assemble the guide conceptual space against the original parts

- Modified the secure block with square type which was circle shape and it raised the long replacing time and easy breakages.

Modification

KNS WIRE BONDER (MODIFICATION).

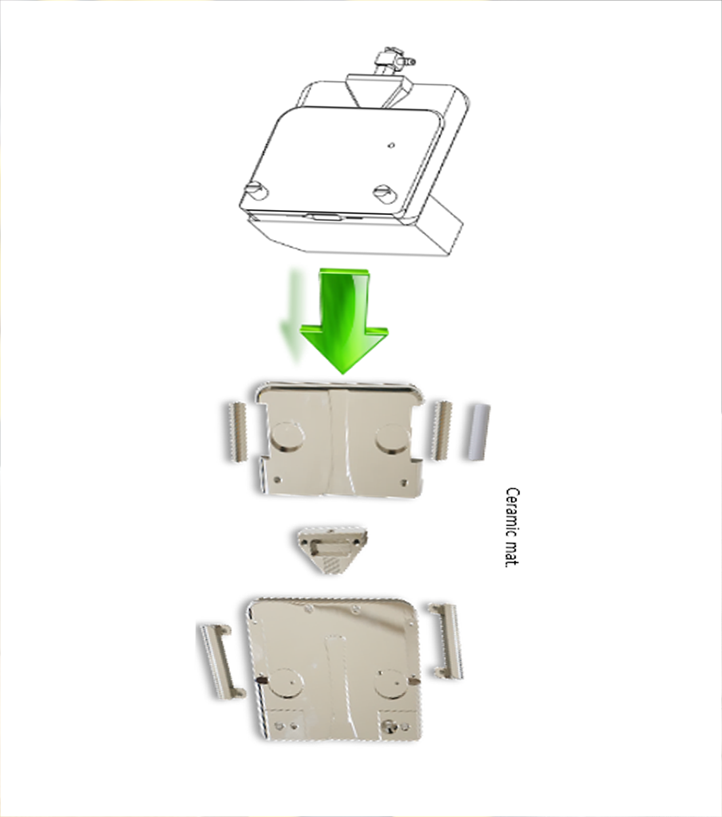

K&S : AIR GUIDE ASSEMBLY (Modify To Improve Life Span)

I-Conn & LA Version (by applying Copper concept which lead the damages in Air Guide area)

Air Guide Assemble Part (problem was Expensive cost) Possibility : part repair concept applied

Air Guide area Parts Localization

- I-CONN & LA

- Air Guide : Contact & Non contact concept

- Drawing : done

- material : Contact Non contact Cost reduction effects

Modification

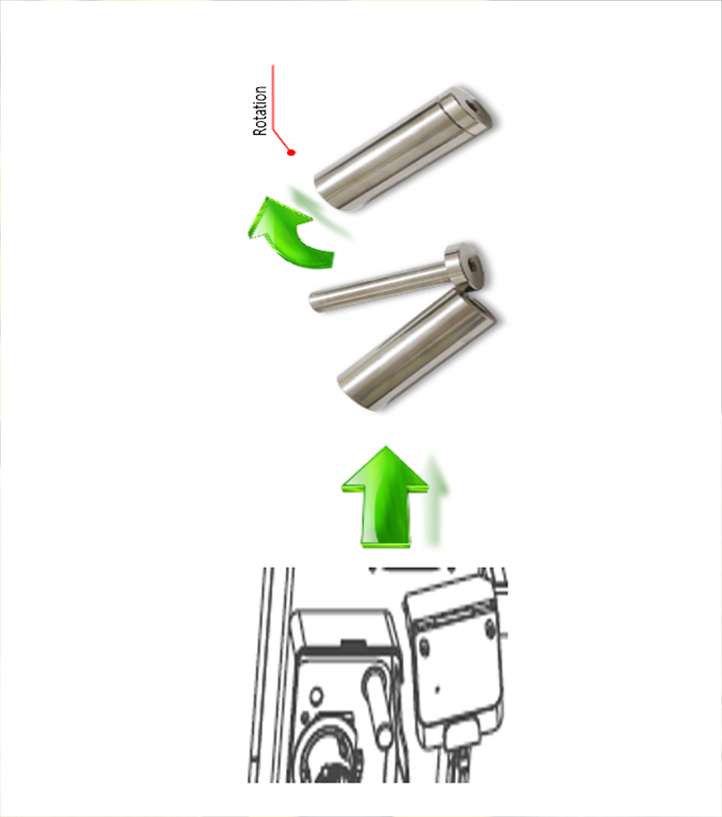

K&S : DIVERTER

Diverter secured in the machine inside/ Maintenance Loss frequently arose

Improved Diverter used parts can be changed the direction

- I-CONN & LA

- Diverter : Wire contact

- Drawing : done

- material : Maintenance Down Loss Rotation and life span innovatively enhanced and gives cost reduction effects

Modification

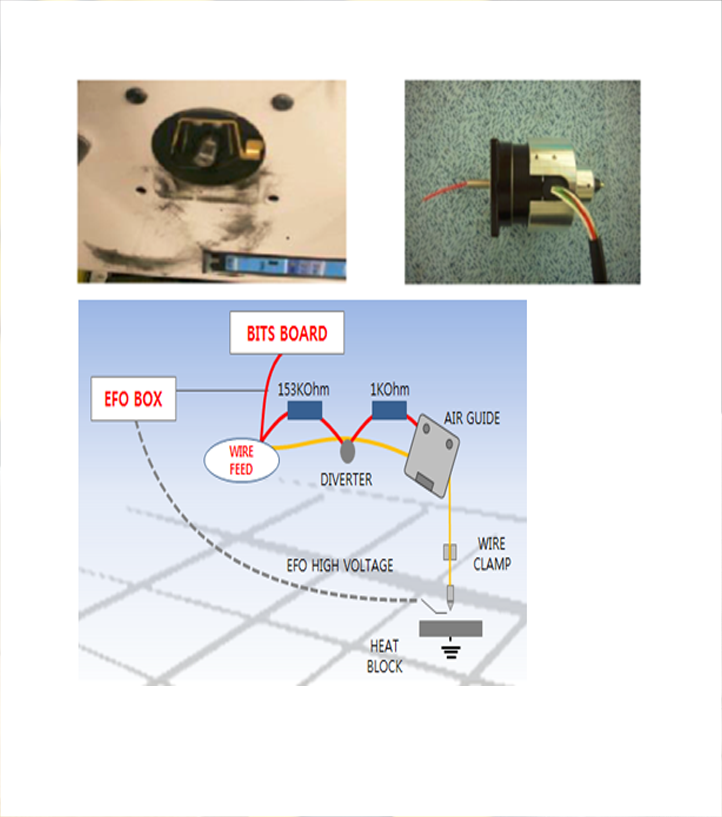

K&S : SPOOL MOTOR SOLUTION (Modify To Improve Wire Bonding Quality)

- Most weakness of KnS W/B the Wire Spool Design change requests from customer to reduces those frequent BITS,EFO error

- ORG Type : Contact Spring type and noise is quite severe regarding resistance force during rotation of Spool motor

- Among device of Copper Wire Bonding/Thin Wire Bonding/AC BITS Type, new issue been arose which is wire wire sticking for the previous modified spool motor.

Before Modify

Wire sticking problem arose worn out and Grey dust surrounding the spool motor area.

After Modify

- Reduces Wire Feed Error

- Sticking issue is not arose by avoiding accumulation of EFO return current between Diverter and Air-Guide

- Occupying the BITS/EFO Return Signal Route leads improve the bonding quality

- MTBA Improvement : 0.43 Hrs ㅡ> 0.5 Hrs

- Productivity amount : 476.47 -> 870.30

- Wire feed error : 668 -> 85

Modification

PRECISION CLEANING SOLUTIONS

Application:

- Stencil / Mesh Cleaning

- Reflow Oven Cleaner, Cooling Coil Cleaner

- De-flux (Flux Cleaning) for Semiconductor SIP, FlipChip, WLCSP, CSP,Wafer Bumping, Substrate and PCBs

- De-greaser / Paint / Epoxy / Oil Remover for metal & precision parts, tooling and metal hardware

Chemical Surfactant

Aqueous Solution

Custom made Chemical Solutions

Modification

CONSUMABLE PARTS AND MACHINERY

Application:

- Semiconductor FOL / EOL

- SMT Machines and Spare Parts, Nozzle, Feeders, Filters & etc.

Details:

- Machine consumable parts (SMT, FOL, EOL)

- SMT Machinery

- Used Refurbish Machinery, Oven, Equipment

- Custom-made Machines

Modification

PRECISION METAL PARTS & MECHATRONICS

Application:

- Precision Parts for Semiconductor, SMT, Electronics andMicro Electro Mechanical System (MEMS).

Details:

- Custom-made Machines

- Thermoforming Tray, Pallets, Jig, Fixture, Tooling